Bleeding Air From Hydraulic System

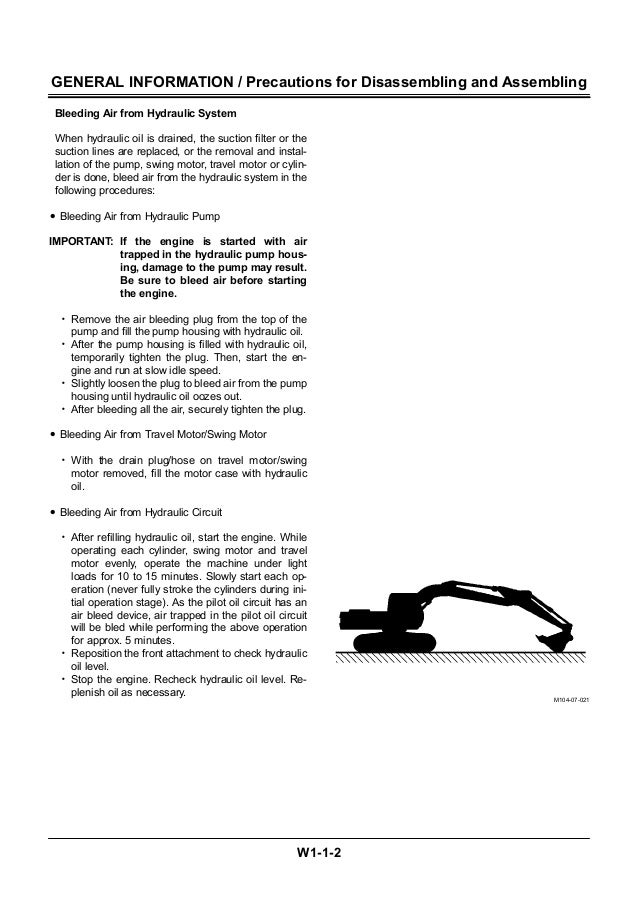

Bleeding air from hydraulic system. But this is not to say that bleeding or purging of air is not a good idea to fast track the process. Hence it is necessary to bleed out the air from a hydraulic braking system. Install the swing lock pin and lower the boom assembly to the ground.

Apart from that it should only bleed one line at a time. This compressed air reduces the amount of force transmitted by the fluid into the hydraulic system. For example air contamination damage may include.

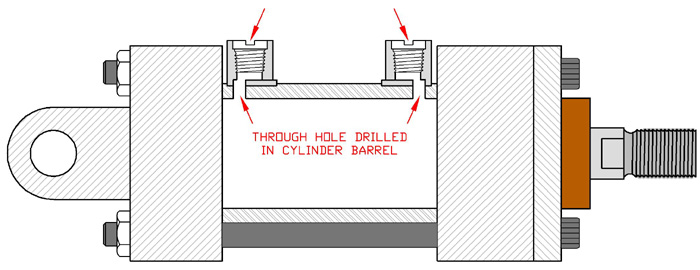

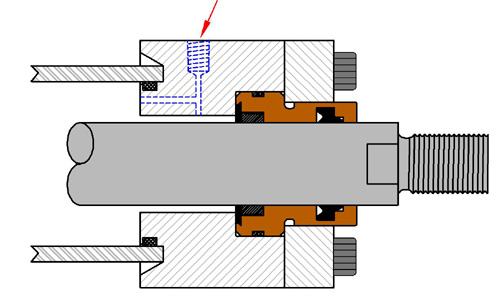

Air bleed valves are used in aircraft hydraulic systems to remove unwanted air from the hydraulic circuit prior to the operation of the high pressure hydraulic system to prevent unexpected and unwanted operational anomalies. This compressed air reduces the amount of force transmitted by the fluid into the hydraulic system. First and foremost its important to bring the air to the top of the cylinder so it can be released more effectively.

How to bleed air from hydraulics system. Reason being air in the system can do damage and result in erratic operation until its removed. Air fits this definition and therefore when air becomes entrained in the oil corrective action is required to prevent damage to both the oil and the other components in the hydraulic system.

Bleeding air from hydraulics should be part of your forklift hydraulic system maintenance practices in Texas. This technique is well-known to mechanics since it can rid most of the air outside new brake fluid. If you are bleeding hydraulic lines from a car youll want to place the car on jacks in the garage or on the street not in the driveway.

The system will self bleed any air just by using it. The following process will help you bleed the air from your single acting hydraulic cylinder to improve its performance. Why is it important to bleed the air from a hydraulic system.

Examples of damage caused. The first and most common method is manual.

Apart from that it should only bleed one line at a time.

Why is it important to bleed the air from a hydraulic system. This compressed air reduces the amount of force transmitted by the fluid into the hydraulic system. This compressed air reduces the amount of force transmitted by the fluid into the hydraulic system. Two methods are used to bleed air from a hydraulic system. If using a Liquid Tie bar Valve part HA5471-2 please refer to the bleeding instructions included with the liquid tie bar valve. Keeping the reservoir filled. Why is it important to bleed the air from a hydraulic system. This technique is well-known to mechanics since it can rid most of the air outside new brake fluid. Reason being air in the system can do damage and result in erratic operation until its removed.

If any amount of air is present in the hydraulic system as the pressure increases the air compresses due to its compressible nature. This is why abnormal noise must always be checked out and careful inspection given to the condition of the systems fluid components and seals to identify any signs of. The process varies slightly depending on the type of cylinder installed and whether you have a bleeder valve on your dump truck cylinder below. The system will self bleed any air just by using it. If you have a leak on the suction side of the pump the pump will continue to draw in air. If using a Liquid Tie bar Valve part HA5471-2 please refer to the bleeding instructions included with the liquid tie bar valve. Keeping the reservoir filled.

Post a Comment for "Bleeding Air From Hydraulic System"